I have built a simple parallel port interface, software oriented, for stepper motors. It can drives two motors, with 500mA output current per phase. As parport cannot directly give this power, we use two ULN2003 darlington array of 7 pairs (we need 8 pairs...).

What you only need is :

Not hard to build ! The board with one motor plugged - The back of the board. Connect the your parallel port pins to the input pins of the ULN2003A, and the output pins of the ULN2003A to the wires of the motor. Put 12V and ground on the ULN and it's done.

Here is the basic code to make it turn: stepper.c and port.h (on linux).

It must be run as root, compiled with a correct PORT value (watch your dmesg).

You think building a 3D scanner is hard ? Take your webcam and check this out !

|

gives: |  |

The main idea was that a mini-itx case is far too much expensive, and is most often made for media centers with a slim optical drive and a 2.5" hard drive. What I wanted is a server, with one or two 3.5" hard drives, and no optical drive. I also wanted an efficient power supply, which is hard to find, so I just considered the lower bound to be not an ATX PSU which is very inefficient with such small loads (around 30W). The mainboard is a Jetway J7F4K1G2E, with a C7 Eden 1.2GHz fanless CPU and two gigabit ethernet NICs. The PSU is a Morex 60W Power Kit No. PDB060R.

|

|

I've made the case as small as possible, with an steel plate for the motherboard, PSU and two 3"1/2 hard drives support and an aluminium plate for the closing panel and the fan support. The air flow is designed to cool efficiently everything: the heatskins of the motherboard (which really needs it, despite what the vendor says), the hard drives (one for now), the RAM, the PSU, and even chips of the motherboard.

Take a look at the gallery.

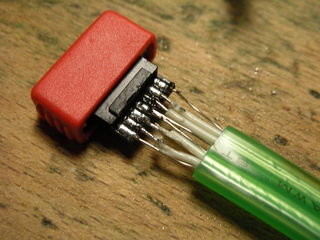

For the above mini-itx case, SATA cables are an issue. The shortest I could find were 45cm (17") long. And finally, one of the cables I bought was badly made, and I decided to open the plug to look for what was wrong. Two wires were unsoldered. It would have been easy to fix, but now I was understanding what SATA cables were made of (2 wire pairs, and 3 grounds given by the shielding), I thought I could cut it off to 5cm. And here it is:

|

|

Take a look at the gallery.